Custom Jewelry Process.

Working with clients to create custom jewelry is a process that requires clear communication and explaining complex industry-specific concepts to an ever-growing client base.

my bespoke jewelry process was crafted to focus on Bridal Jewelry, as engagement rings are often a customer’s entry-point to fine jewelry. The market for custom and semi-custom fine jewelry has been expanding as young consumers demonstrate a growing interest in sustainability, customization, sourcing and experience in the process.

one of my greatest strengths in the custom design process is on-boarding my clients to the language of diamonds and gemstones, design, and production. creating a common language with my customer has allowed me not only to set clearer goals and expectations, but also gives the client a greater sense of agency and engagement in the experience.

Below is a breakdown of my process.

1. we meet

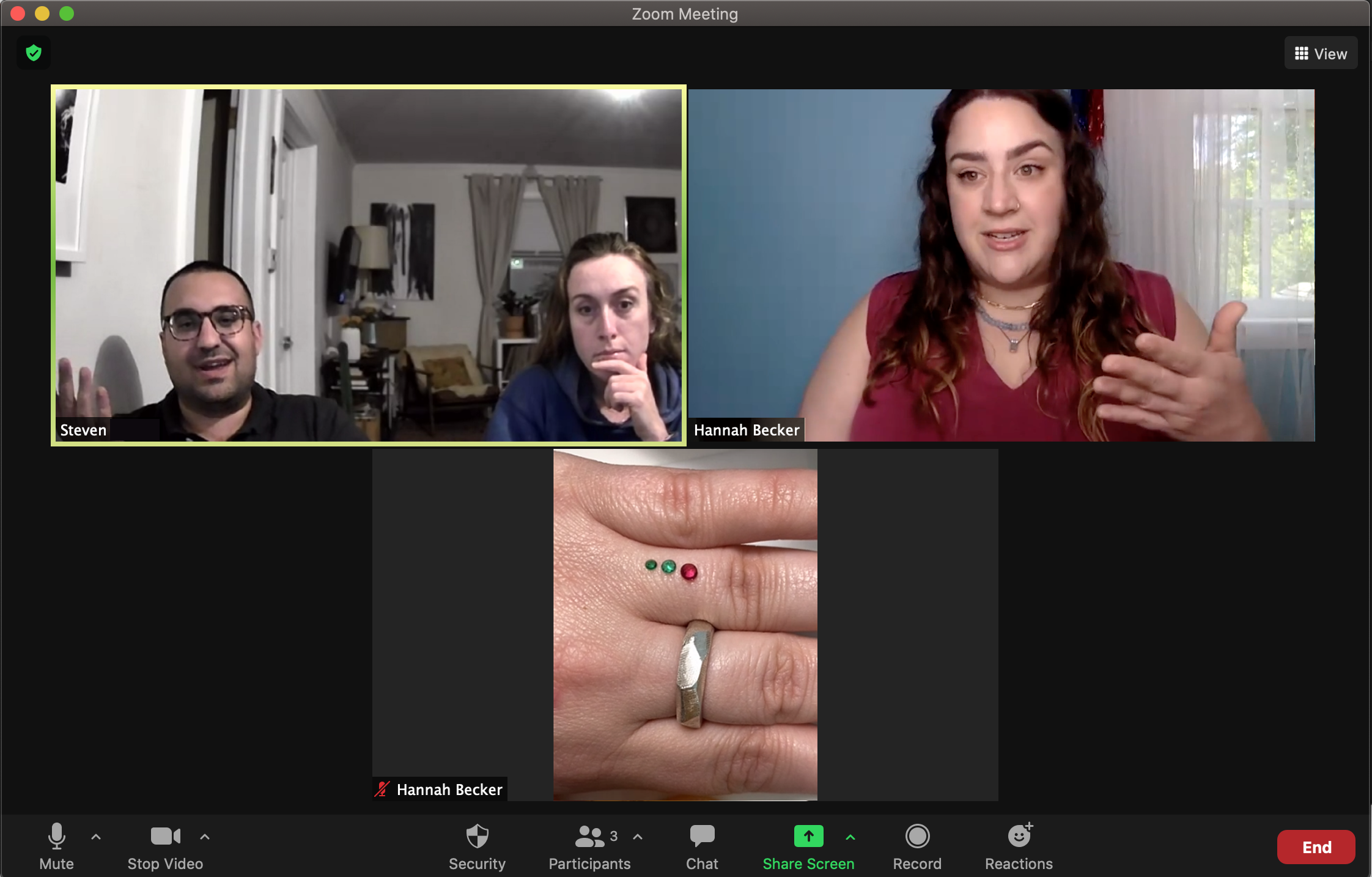

Whether in person, or over zoom, the first step of the custom process is meeting with the client. At this beginning stage of the process i spend time introducing the client to the world of fine jewelry and gemstones with a presentation that breaks down the 4c’s of diamonds, and an overview of colored gemstones, metals, and the “parts” of a piece jewelry.

This meeting is where i establish budget, timeline, look over any jewelry/stones the client already has for the project, and consider any design ideas or inspiration they already have in mind.

2. i source

a majority of the custom jewelry i create features a center stone as a focal point. sourcing this stone is essential to the design process as it dictates integral details of size, scale, and fit. The sourcing process looks different based on if the client is viewing stones in person or remotely.

For in-person clients, we meet and look over 3-8 stone options that i source from an expansive group of vendors i have vetted.

For my remote clients, i create a stone dossier with images, videos, specs, pricing, and my detailed comments about the benefits of each stone in the context of our project.

with both presentation styles, i have had great success with client sourcing by providing an ample selection of stones that fit the original “ask”, but also showing them wild card options that stand out to me as a gemologist and designer.

3. i design

the design process ranges from simple to intricate and each client comes with a different set of needs and ideas for the project. During the custom process, we discuss the significance of the piece we are making, and who we are making it for. These conversations allow me to gather personal details about the client, the couple, and the occasion we are celebrating that i can translate into my designs.

Sometimes, that takes the form of a hidden book shape in the gallery of a ring for an english teacher with an obsessive love for literature. Other times it’s adding a pop of color by setting the groom’s birthstone to an engagement ring or hiding the couple’s initials in a piece. adding these intimate personal details offers my client a unique sense of ownership over the custom process and allows me to add an extra spark of personality to a design.

The first designs a client sees are in a design dossier. LIke the stone dossiers, these presentations include comments and specification details alongside digital drawings i have created of each piece.

The bottom image demonstrates the design editing process. Often a client will like an element of one design and want to pair it with another. This image shows a mix of finishing details for the client to select in an à la carte manner.

4. we make

The manufacturing process is comprised of a number of steps that i take on, and i regularly check in with my clients along the way. my experience in quality control and production management for both high jewelry one-of-a-kind pieces and production lines has helped me to perfect this process with my vendors.

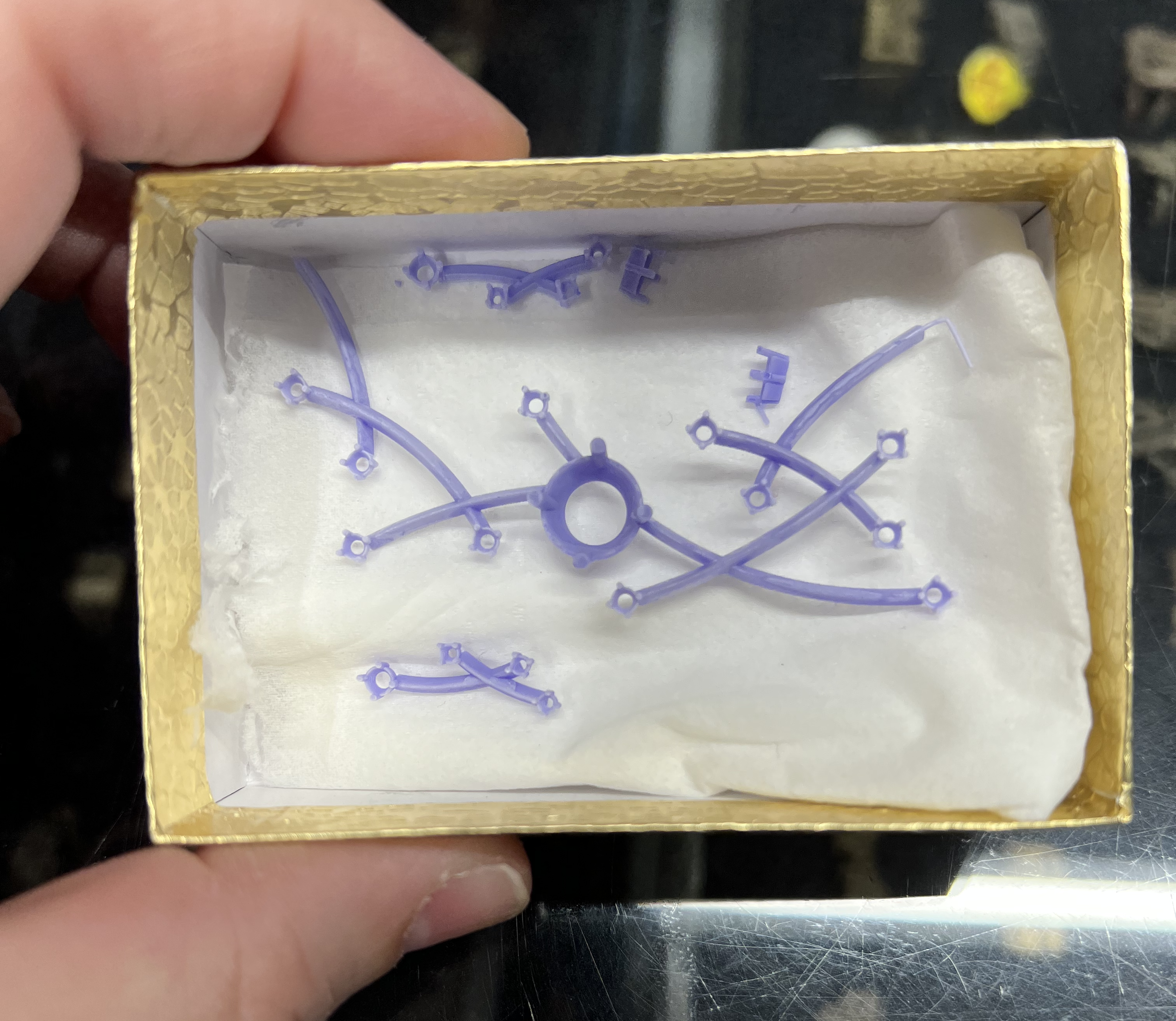

the first step in taking a design the client has approved in the design phase to a finished piece of jewelry is Cad. with training in rhino and gemvision matrix software, i frequently create the cad models for the jewelry i produce for my clients. during busier moments, i utilize outside vendors for this step. these cad models are shown to the client for approval before being 3d printed.

cad models are 3d printed by a vendor, and i inspect them before casting. i have experience running 3d printers and casting, but it is not cost effective for me to do either of these things in house.

the 3d printed model then gets sent to the casting house to be cast in metal before the jewelry work is done.

I inspect the metal casting and then send with it’s accompanying stones and findings to my master bench jeweler to be assembled, have stones set, and get polished.

I am still cultivating my bench skills. i do not work on the custom pieces for my clients, but i do the metal work and some of the stone setting for the ready-made pieces i sell.

5. we deliver

i carefully inspect each piece when i receive it from the jeweler. I then package each piece for gifting and deliver it to my client.

then my client gets to complete the gifting process!